Introduction

Chemical plants are the most demanding projects in today’s engineering world. The risks from hazardous chemicals and the investment involved make the role of a structural engineering partner absolutely crucial. A chemical plant must be designed to protect lives, environment and capital assets. In these projects structural engineering is not a secondary concern but the foundation upon which safety, operational continuity and regulatory compliance depends.

Project management and construction of a chemical plant involves civil engineering teams that must show leading edge engineering expertise. A structural engineering firm that works closely with its clients can deliver innovative structures and provide comprehensive services that ensures efficient project management and safe operations. Every structural engineer and structural engineers working on these projects must use advanced software and modern technology to achieve outstanding results in design and construction.

Chemical Plant unique challenges:

The unique challenges include handling heavy equipment loads, managing complex pipe racks with thermal expansion and corrosive environments. A single mistake by a structural engineer or structural engineers can impact the entire built environment. For chemical plant projects safety is paramount; every structural engineer must commit to adhere to strict safety standards and innovative solutions.

When choosing an engineering firm the focus must be on not just cost but on engineering expertise, proven project outcomes and ability to work with other professionals.

In this article we will guide project managers, procurement specialists and decision makers through a structured process to choose the right structural engineering partner for chemical plant construction.

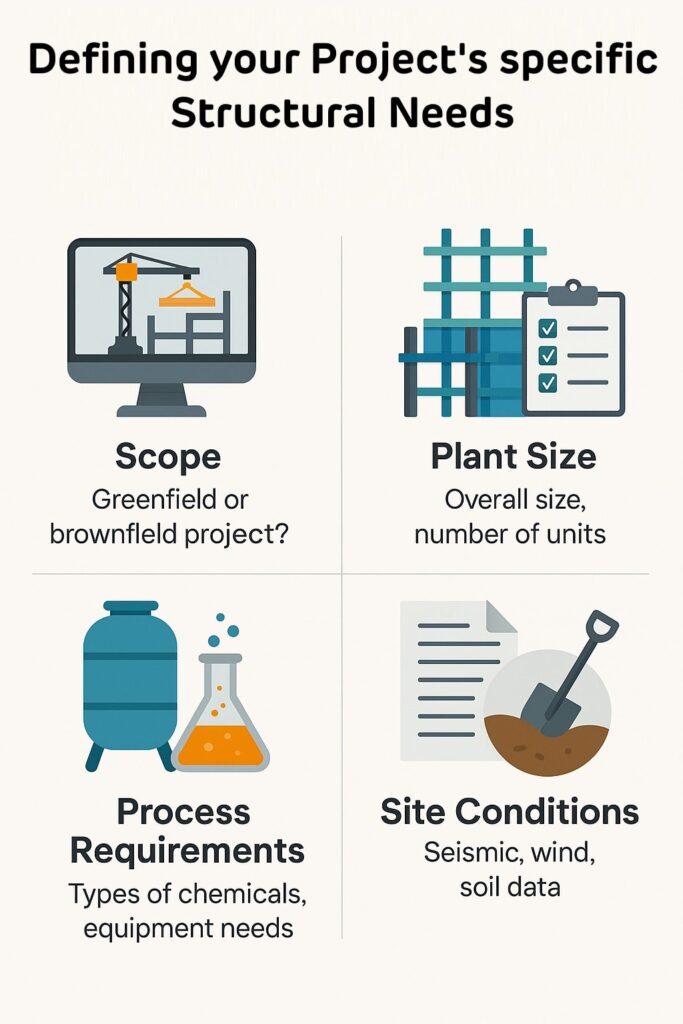

Step 1 – Defining Your Project’s Specific Structural Needs

Before contacting potential engineering services, it is essential to define your project’s specific structural requirements. Start by analyzing the scope: is this a greenfield or brownfield project? A chemical plant project may be a new build or significant expansion of existing infrastructure projects. Consider the overall plant size, number of units and the estimated structural tonnage or concrete volume required. Next, assess process specific requirements. The type of chemicals handled in a chemical plant can dictate the selection of materials and design techniques. For example a chemical plant processing corrosive substances requires engineers with knowledge of new materials and durable coatings. Heavy equipment such as reactors, columns, compressors and storage tanks requires specialized support solutions. Structural engineers must design foundations that account for vibration isolation and thermal loads. In every infrastructure project project management requires a detailed geotechnical report, local building codes and environmental impact studies to ensure engineering expertise is applied correctly.

Site conditions further complicates matters. Geographical location determines seismic zone classification, wind load parameters, snow/ice loads and ambient temperature ranges. Civil engineers must work closely with geotechnical teams to integrate soil bearing capacity data and groundwater conditions. Structural engineering companies that offer innovative solutions in sustainable design and sustainable infrastructure are best positioned to meet these challenges. The deliverables for the project may include detailed calculation reports, full range of drawings such as general arrangements, details and shop drawings and digital BIM models to support construction services.

BIM requirements including Level of Development (LOD) standards must be clearly defined. Does your project require a particular BIM platform? The chosen structural engineering firm must demonstrate expertise in using advanced software and integrating digital models for clash detection and data management. Budget and schedule constraints alongside desired project efficiency must be communicated to ensure the selected engineering firm can meet every expectation.

Learn how advanced digital deliverables can streamline your project, check out BuildTwin’s CAD Design & Drafting Services. Know more about CAD Design & Drafting Services

Step 2 – Key Criteria for Evaluating Structural Engineering Vendors

Develop a scorecard to evaluate engineering services. This scorecard should be weighted according to your project’s specific needs. The following criteria will help you narrow down your choices:

A. Technical Expertise & Specialization

- Chemical Plant Experience: Ask for a list of completed chemical plant projects. The best engineering firm will have a rich history of designing structures for chemical plants and power stations and will have delivered outstanding results. Structural engineering companies that have a proven track record in chemical plant projects demonstrate a deep understanding of process industry specific structures such as pipe racks, vessel foundations and tank farms.

- Specialized Knowledge: Look for structural engineering expertise in heavy industrial structure design, foundation design (including machine foundations and dynamic analyses) and blast resistant design. The firm’s structural engineers must integrate geotechnical data into structural design and work closely with professionals to ensure innovative solutions are achieved.

- Codes & Standards Proficiency: Verify that the firm’s engineers are familiar with international and local codes such as ASCE 7, ACI 318, AISC 360, and API standards. This ensures every structural engineer working on your project meets strict safety standards.

For precise detailing, explore BuildTwin’s Rebar Detailing Services which help ensure that every rebar drawing is thoroughly checked and compliant

Know more about Rebar Detailing Services

B. Experience & Track Record

- Project Portfolio: Review case studies and client references. Look for evidence of successful project outcomes in chemical plant projects and renovation projects. Experienced structural engineers with a long list of projects provide the engineering expertise that guarantees design and construction services.

- Firm Stability: The consulting firm’s rich history is critical. An engineering firm that has been in business for decades is likely to provide stability and a full range of professional services.

C. Resources, Capabilities & Technology

- Team Depth: Assess the size and experience of the engineering team. Structural engineers, along with civil engineers, must have proven qualifications and registrations. The engineering firm should work closely with senior personnel to oversee every design and detail.

- Software Proficiency: Confirm that the firm uses advanced software such as STAAD.Pro, SAP2000, RISA-3D, ETABS, and Tekla Structures for structural design. This modern technology and advanced software ensure innovative approaches to design and construction.

- BIM Integration: A firm with high BIM maturity will deliver efficient digital models that improve project efficiency and reduce rework. Their ability to work closely with building systems and other disciplines is key.

Discover how integrated BIM solutions enhance project coordination. Know more about BIM Services.

D. Quality Management & Safety Focus (The “Process & Culture”)

- Quality Systems: The firm should have ISO 9001 certification or an equivalent quality management system. The procedures for design checking and inter-discipline reviews are a testament to their commitment to ensuring safety.

- Safety Commitment: Look for structural engineers who prioritize safety. Their commitment to ensuring safety throughout the design and construction phases is essential.

E. Project Management & Collaboration (The “Workflow”)

- Management Approach: Evaluate the firm’s project management methodology. Their ability to integrate construction management with engineering services is critical for on-time and on-budget project outcomes.

- Communication: Effective communication protocols and responsiveness indicate that the firm will work closely with your team and contribute to improved project outcomes.

- For a seamless project experience, check out BuildTwin’s integrated ERP solutions that enhance live project tracking and vendor communication Explore Projects.

F. Commercial Viability (The “Cost & Contract”)

- Pricing & Value: Review the pricing structure and contractual terms. Lowest bid does not always means best value. Choose a firm that provides clear and transparent pricing and delivers innovative solutions that maximize project efficiency.

- Financial Stability: Ensure the engineering firm is financially stable and capable of supporting large scale projects from conception through to completion.

Step 3 – The Selection Process Workflow

After defining your needs and evaluation criteria, follow a systematic selection process:

- Initial Screening/Longlisting: Identify potential engineering firms with a strong background in chemical plant projects. Look for those with extensive experience in structural design and construction.

- RFI/RFQ: Issue a Request for Information or Qualifications to gather detailed information about the engineering firm’s capabilities. Ask the structural engineers to demonstrate how they deliver innovative solutions and sustainable development.

- Shortlisting: Score the responses and select a group of three to five structural engineering companies. These should be firms that have demonstrated engineering expertise and the ability to deliver on complex infrastructure projects.

- RFP: Invite the shortlisted firms to submit detailed proposals that address your project requirements, including BIM and advanced software integration.

- Proposal Evaluation: Develop a weighted scoring matrix to evaluate technical proposals and commercial offers. Structural engineers must present a clear methodology that supports project management and safety.

- Interviews & Clarifications: Conduct meetings to discuss proposals and meet key personnel. This step helps you assess if the firm’s engineers work closely with your team.

- Reference Checks: Contact client references to verify the firm’s track record in chemical plant projects and other major infrastructure projects.

- Final Selection & Negotiation: Select the engineering firm that best meets your criteria and negotiate final terms to secure a partnership built on innovation and expertise.

BuildTwin’s marketplace brings pre-qualified structural vendors directly to your fingertips. Know how BuildTwin helps chemical plant engineering project >>

Understanding the Provider Landscape

When evaluating the provider landscape, consider full-service EPC(M) companies. They offer global design perspective and deliver full range of professional services. But for projects that require specialized focus on structural design, look for consulting firm partners that have dedicated structural engineers with industry knowledge.

Durchgeplant

Website: durchgeplant.eu

Location: Germany

Overview: Durchgeplant is a focused structural engineering firm with a dedicated specialization in chemical plants alongside other sectors. With a team of 28+ professionals, they offer a comprehensive range of services including structural design, BIM modeling, project management, and detailed precast as well as cast-in-situ detailing. Their strong local presence in Germany and experience in delivering production halls and logistics centers make them a strong candidate for chemical plant projects.

Mold-Tek Technologies Limited

Website: moldtekengineering.com

Location: India, USA, Middle East, Germany

Overview: With a large team of 1100+ employees, Mold-Tek specializes in sectors including chemical plants. Their offerings include full structural services with a particular emphasis on structural steel detailing and precast detailing—key capabilities for chemical plant construction where heavy equipment and corrosive environments demand robust detailing and precision. Their extensive experience and multinational presence add significant credibility for large-scale, complex projects.

J&F

Website: jf.ag

Location: Offices in India, USA, EU, Middle East, UK, Germany, Australia

Overview: J&F is a sizable, multinational consulting firm with a diverse project portfolio. They list chemical plants among their specialized sectors and offer a range of services from MEP to structural, along with BoQ/QS and BIM modeling. Their extensive geographic reach and broad expertise enable them to support complex chemical plant designs and coordinate multidisciplinary efforts effectively.

GBC Engineers

Website: gbc-engineers.com

Location: Vietnam and Germany

Overview: With a team of over 200 professionals, GBC Engineers covers a wide range of industrial and infrastructure sectors—including chemical plants. Their service portfolio includes structural design, PEB design and detailing, BIM modeling, and project management services. Their ability to integrate digital workflows with traditional engineering practices makes them well suited for the high-precision and safety-critical nature of chemical plant projects.

Trikaal Tech Enterprises Private Limited

Website: trikaaltech.com

Location: India

Overview: Although a smaller firm with 70+ employees, Trikaal Tech Enterprises offers an extensive suite of engineering services. They explicitly list chemical plants among their specialized sectors and provide detailed engineering, structural design, structural steel detailing, BIM modeling, and even BoQ/QS services. Their comprehensive offerings and focus on both design and digital detailing (including precast design) make them a strong contender for specialized chemical plant structural projects.

Fluor Corporation

Fluor brings decades of experience managing complex infrastructure and industrial projects, including chemical plants. The firm’s structural engineering services emphasize innovative, code-compliant designs that support heavy equipment, dynamic loads, and challenging environmental conditions. Fluor’s advanced use of digital tools and BIM integration ensures precision and efficiency throughout the design and construction phases, making them a trusted partner for high-risk projects.

https://www.fluor.com/

Bechtel Corporation

With a legacy dating back over a century, Bechtel is renowned for its comprehensive engineering, procurement, construction, and project management services. Their structural engineering division has successfully executed chemical and petrochemical projects across the globe. Bechtel’s rigorous design methodologies and commitment to safety standards ensure that their structural systems can reliably support heavy process equipment and withstand extreme operational conditions.

https://www.bechtel.com/

Technip Energies

Technip Energies specializes in engineering and technology solutions for the energy and chemical sectors. Their structural engineering services focus on innovative, future-ready designs that incorporate advanced analytics, BIM, and sustainable development practices. By integrating digital workflows with traditional engineering disciplines, Technip Energies delivers robust and efficient designs that meet the unique challenges of chemical plant construction.

https://www.technipenergies.com/

Worley

Worley offers a full spectrum of engineering services for the chemicals and resources sectors. Their structural engineering capabilities include designing foundations, structural frameworks, and specialized support systems to manage heavy, dynamic loads typical of chemical plants. Worley’s holistic approach—combining engineering expertise with advanced software tools—ensures that projects are delivered with the highest quality, safety, and cost efficiency.

https://www.worley.com/

Red Flags – What to Watch Out For

Certain warning signs may indicate that an engineering firm is not the right partner:

- Vague or generic responses about chemical plant experience.

- Over-reliance on subcontracting core engineering services without clear oversight by experienced structural engineers.

- Inability to provide specific client references or detailed case studies.

- Poorly defined quality management or QA/QC processes.

- Resistance to using the required BIM platforms or advanced software.

- Proposals that neglect to address the unique challenges of chemical plant structural engineering.

- Unrealistically low bids that suggest compromised engineering expertise or reduced construction services quality.

Conclusion

Choosing the right structural engineering partner for your chemical plant project is a high-stakes decision. By outlining your project requirements, assessing technical expertise and project management capabilities and following a structured process you will set yourself up for success. In the end a good engineering firm that delivers innovative solutions and works with all stakeholders will build your infrastructure to the highest level of standards. If you’re ready to take the next step in securing expert structural engineering services and want to know more? Book a Call>>