A Common Data Environment (CDE) is the digital backbone that leverages technology to transform isolated BIM processes into a cohesive, end-to-end workflow for structural engineering and construction. It serves as the single source of truth, centralizing models, documents, schedules, photos, RFIs, and cost data under controlled access and versioning.

Understanding CDE in Structural Engineering For Construction projects

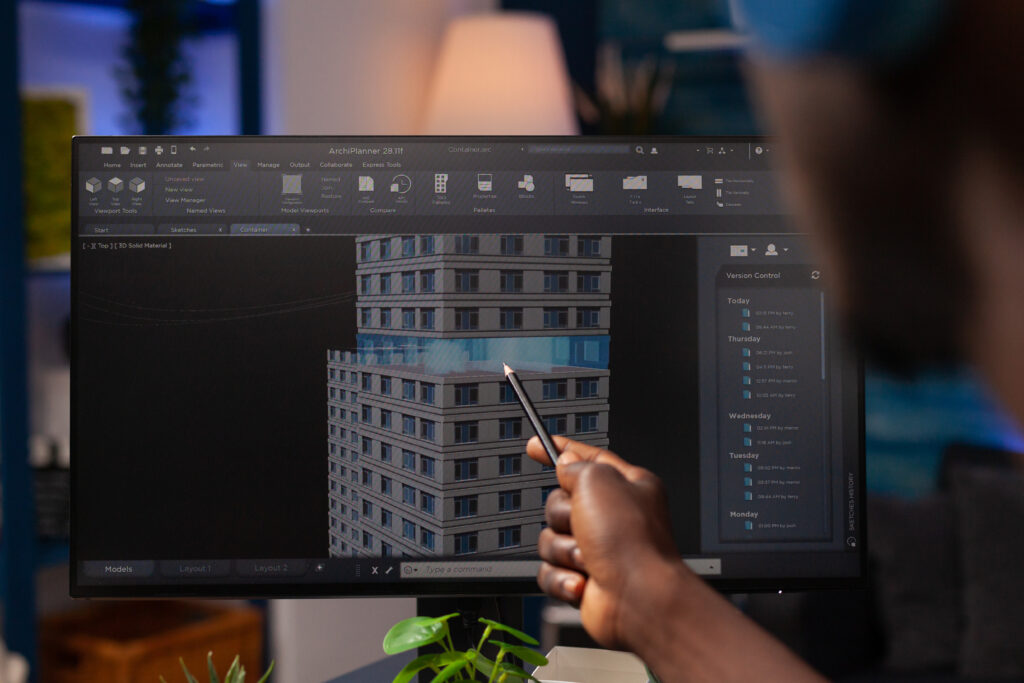

Structural projects today generate volumes of data—from test analysis results to on-site photos and contracts—creating a “data deluge” that overwhelm teams unless rigorously managed. BIM emerged to organize this information into intelligent digital models, but without a Common Data Environment, BIM workflows fragment and produce errors. A CDE is the centralized digital repository that underpins collaborative BIM, enforcing controlled access, version control, and standardized naming to ensure every engineer and contractor works from the same, up-to-date information. This article explores the interplay between CDE and BIM—how they together transform structural engineering workflows for construction teams , deliver efficiency and quality, and what challenges lie ahead.

What is Building Information Modeling (BIM)?

Core Concept: BIM is more than 3D geometry; it is the holistic process of creating, managing, and sharing structured, multi-disciplinary data for a built asset across its lifecycle—from planning and design through construction and operations.

- Key Dimensions:

- 3D: Spatial geometry and relationships.

- 4D: Time/schedule integration for construction sequencing.

- 5D: Cost estimation and budget tracking.

- 6D: Sustainability metrics and facility management data.

These dimensions turn the BIM model into a living information resource, guiding structural design choices and contractor packages

BIM in Structural Engineering: Structural teams leverage BIM for conceptual framing, parametric optimization of steel and concrete elements, clash detection with architectural and MEP disciplines, and direct generation of analysis models for tools like ETABS or STAAD.Pro.

What is a Common Data Environment (CDE)?

Core Definition: A CDE is the agreed source of information for a project, centralizing the storage, management, and dissemination of every “information container” (models, drawings, documents, reports) through managed processes.

ISO 19650 Definition: ISO 19650 formally defines a CDE as an “agreed source of information for any given project or asset, for collecting, managing and disseminating each information container through a managed process”.

CDE vs. Traditional Methods: Unlike emails, file servers, or basic Document Management Systems, a CDE supports BIM workflows with model viewing, clash detection integration, and automated transmittals, eliminating silos and version confusion.

- Purpose:

- Storing: Secure, centralized storage of all project data.

- Managing: Controlled access, version control, and audit trails.

- Disseminating: Automated workflows for approvals, submittals, and RFIs.

Relationship Between CDE And BIM

- CDE as the Backbone: BIM’s collaborative potential hinges on a CDE to host federated models and structured data, ensuring models are version-controlled and accessible across teams.

- Managing BIM Data: A CDE enforces naming conventions and file status codes (WIP, Shared, Published), gating BIM data flow to preserve information integrity and drive standardized ISO 19650 workflows.

- Single Source of Truth: By serving as the definitive repository, a CDE ensures structural engineers always work on the latest BIM iteration, reducing rework and errors.

- Facilitating BIM Workflows: Approval routing, clash detection feedback, and issue tracking are built into modern CDE platforms—streamlining BIM coordination meetings and model reviews.

CDE & BIM Workflows in Civil Engineering

Structural Design & Modeling Workflow

- Conceptual & Preliminary Design: Engineers use BIM tools (Revit, Civil 3D) to develop early structural concepts within a CDE, enabling rapid option studies and stakeholder reviews in a controlled digital space.

- Detailed Structural Modeling:

- Multi‐Material Models: Create reinforced concrete, steel, and composite element models within BIM, all stored and versioned in the CDE.

- Parametric Modeling: Parametric constraints allow quick iteration of column grids or brace configurations; every update is tracked in the CDE audit trail.

- Information Exchange: Standardized formats like IFC enable sharing structural models with architects and MEP teams through the CDE hub, ensuring cross-disciplinary coordination.

ISO 19650 Workflow in CDE

| State | Description |

|---|---|

| WIP | Model/drawings under internal development,restricted access within structural team. |

| Shared | Post–internal QA,available in CDE for clash detection and coordination reviews. |

| Published | Approved by lead engineer/client,released for construction documentation. |

| Archived | Historical versions retained for audit and lessons-learned. |

Structural Analysis Integration

- Linking Physical & Analytical Models: BIM tools (Revit + Analytical Modeler) maintain the correlation between geometry and analysis-ready finite element models, automatically syncing updates via CDE storage.

- Data Exchange with Analysis Software: Export–import workflows using IFC or vendor APIs move models into ETABS, SAP2000, or STAAD.Pro; the CDE tracks versions and metadata to prevent mapping issues.

- Challenges & Benefits: Interoperability gaps may cause data loss, but robust CDE governance reduces synchronization errors and accelerates analysis model preparation.

- Storing Analysis Results: Analysis reports, utilization plots, and calculation spreadsheets are stored alongside BIM files in the CDE, preserving the complete design rationale.

Structural Detailing & Documentation

- Generating Drawings from Models: 2D plans, sections, and reinforcement details are automatically extracted from the BIM model in the CDE, ensuring drawings match the current model state.

- Reinforcement & Rebar Modeling: 3D bar cages in Tekla Structures or Revit are managed in the CDE, enabling clash-free coordination with embed schedules.

- Steel Connection Design & Detailing: Detailed joint models, produced in specialist tools, are linked back to the central BIM model via the CDE, maintaining single-source integrity.

- Automated Documentation: Schedules (beams, columns, rebar counts) and bills of quantities are generated directly from CDE-hosted model data, reducing manual errors.

Fabrication & Construction Workflow

- Sharing Fabrication Data: CNC files and shop drawings derived from the BIM model are securely transmitted to fabricators using the CDE’s permission-controlled fabricator workspace.

- Construction Sequencing (4D BIM): Linking structural model elements in the CDE to the project schedule creates visual 4D simulations for site planning.

- Quantity Take-off & Cost Estimation (5D BIM): Extracted material quantities drive cost codes in ACC’s takeoff module or ProjectWise Deliverables, tightening budget controls.

- Site Access & Coordination: Field teams access the latest structural drawings on mobile devices via the CDE’s web interface, ensuring “right-version” usage on site.

- Issue Management & RFIs: RFIs linked to specific model elements are logged in the CDE, enabling rapid resolution and traceable audit trails.

Handover & Operations

- As-Built Structural Model: The BIM model in the CDE is updated to reflect actual built conditions, capturing deviations for accurate record.

- Digital Twin Foundation: The CDE-managed structural BIM model feeds into digital twin platforms, integrating sensor data for ongoing health monitoring.

- Asset Information Management: Facility managers retrieve structural data—material properties, load capacities, maintenance logs—from the CDE or connected asset management systems.

Integration, Tools, and Standards

CDE Integration with Structural Engineering Software

- Importance of Interoperability: Seamless data exchange between the CDE and analysis/detailing tools is vital to avoid data silos and rework.

- Analysis Software Integration: Native plugins and IFC/CIS/2 conversions connect CDEs with ETABS, SAP2000, STAAD.Pro, RISA-3D, and Robot Structural Analysis, preserving model fidelity and metadata.

- Detailing Software Integration: Tekla Structures and Revit Detailer workflows push/pull data to/from the CDE via API or cloud connectors.

- Role of APIs and Open Standards: IFC enables neutral geometry exchange; BCF standardizes issue tracking; openCDE APIs foster cross-platform data sharing.

Common CDE Platforms Used in Structural Projects

| Platform | Strengths | Example Use |

|---|---|---|

| Autodesk Construction Cloud | Deep integration with Revit/Civil 3D; robust docs control | SaaS skyscrapers, mixed-use towers |

| Bentley ProjectWise | Enterprise document/workflow automation; iTwin integration | HS2, Crossrail, large infrastructure |

| Trimble Connect | Open BIM, field-to-office workflows; Quadri integration | Road reconstruction pilots, bridges |

| Oracle Aconex | Immutable document control; JV environments | Global airport and rail JVs |

| Procore | Project management with CDE features | Mid-sized construction projects |

Selecting the Right CDE

Key considerations include project scale, BIM maturity, existing software ecosystem, security and compliance requirements, and budget constraints.

Standards and Protocols

ISO 19650 Series: Defines CDE structures, naming conventions, and workflows for BIM projects.

BS 1192: Historical precursor emphasizing collaborative data environments.

File Naming Conventions: Standardized codes (e.g., BS EN ISO 19650-2 schema) ensure intuitive organization.

LOD (Level of Development): Specifies the required detail in structural elements at each design stage.

Data Exchange Formats: IFC for model data; CIS/2 for steel structures; BCF for issue collaboration.

National BIM Mandates: Many governments mandate CDE use; e.g., UK BIM Mandate for public projects.

Benefits of CDE & BIM for Structural Engineering

Improved Collaboration & Coordination: Central data hub reduces interdisciplinary clashes and fosters clear communication across architects, civil engineers, MEP, and contractors.

Enhanced Design Quality: Tight integration of analysis and parametric modeling uncovers optimizations early, reducing design iterations.

Reduced Errors & Rework: A single source of truth eliminates out-of-date drawings; early clash detection cuts site clashes by up to 50% in some projects.

Increased Efficiency & Productivity: Automated documentation and take-offs save up to 30% of drafting time.

Better Data Management & Integrity: Version control, audit trails, and role-based access strengthen data security and ensure efficient traceability.

Improved Risk Management: Full transparency of information flow enables proactive mitigation of design and construction risks.

Streamlined Fabrication & Construction: Clear hand-off of model data to fabricators reduces shop drawing revisions by 40%.

Lifecycle Value: CDE-driven digital twins inform preventative maintenance, extending asset life and reducing O&M costs.

Challenges in Implementing CDE & BIM in Structural Engineering

Resistance to Change & Adoption Barriers: Cultural inertia and lack of CDE planning in early phases hamper deployment, particularly among experienced engineers .

Software Interoperability Issues: Gaps in IFC support and mapping between BIM and analysis tools require workarounds.

Cost & Training: Upfront investment in platforms and staff training can be significant.

Data Security & Access Control Complexity: Managing permissions across diverse organizations demands robust governance.

Standardization Gaps: Enforcing consistent naming and LOD standards among stakeholders remains difficult.

Defining Workflows & Responsibilities: Clear roles for WIP, Shared, and Published states are essential to avoid confusion.

Examples

HS2 (UK): Used BIM 360 and ProjectWise, as part of a broader system to centralize data across contractors and client systems. Phase 1 of HS2 involved over 150,000 document deliverables and millions of asset data points, enabling up-to-date geotechnical data sharing.

Crossrail (Elizabeth Line, London): Used Bentley ProjectWise alongside Synchro Pro and Navisworks to create 4D models (integrating 3D designs with schedules) and 5D (cost integration). This improved planning and reduced clashes.

Over 40 sites and 10,000 workers were involved, Crossrail’s Common Data Environment (CDE) integrated data from multiple stakeholders, including contractors.

While BIM improved safety planning (e.g., virtual simulations for hazard detection). Crossrail’s Paddington Station achieved a 65% saving in time and paper costs through digital redline drawings.

Crossrail’s BIM processes ensured asset data was structured for seamless handover to Transport for London (TfL), including GIS-linked asset databases.

Shanghai Tower: The Shanghai Tower used Revit (Architecture, Structure, MEP) for design and Navisworks for coordination. Autodesk Consulting provided training and a cloud-based CDE. The project involved over 30 consulting firms and subcontractors, each contributing various components . Parametric BIM models optimized the tower’s twisted form, reducing wind loads by 24% and saving $50 million in materials. The BIM database became the “DNA of the building,” supporting lifecycle management and LEED Gold certification

Future Trends

Cloud-Based BIM & CDE Dominance: Continued shift to SaaS platforms for anywhere, anytime access.

Enhanced Interoperability & Open Standards: openCDE initiatives will enable cross-platform data exchange without loss.

AI & Machine Learning Integration: Generative design for structural optimization; AI-driven clash detection and risk prediction.

Digital Twins & IoT: Live sensor data fed into CDE-based digital twins for commercial structural health monitoring.

AR/VR Integration: Immersive model reviews and on-site guidance.

Prefabrication & Modular Construction: CDE-driven workflows powering off-site manufacturing and logistics.

Sustainability Focus: Lifecycle carbon tracking and embodied carbon calculations within the BIM/CDE ecosystem.

Blockchain Potential: Immutable transaction records for contracts and payments managed within the CDE.

Conclusion

Common Data Environments have evolved into the indispensable infrastructure for BIM-driven structural engineering and construction. By unifying all project information—models, documents, and data—under controlled workflows, CDEs eradicate silos, enhance collaboration, and underpin advanced BIM processes from analysis through digital twin handover. While implementation challenges persist—interoperability, training, and governance—the demonstrated productivity gains, risk reduction, and lifecycle value underscore that CDE adoption is no longer optional but essential for modern structural professionals. Platforms like BuildTwin elevate this further by merging a global Marketplace with an integrated ERP, AI-powered quality control, and seamless CDE integrations. Know More!