Introduction

Under the hum of machinery and the sprawl of assembly lines, it’s the silent force that keeps everything running smoothly. Or not. Choosing the right structural engineering firm can make all the difference between a project that hums along and one that’s plagued by costly delays.

That’s why selecting the right structural engineering companies for a manufacturing plant is a decision that can make or break your infrastructure projects. In today’s competitive construction industry, civil engineering and structural engineering professionals need to come up with innovative solutions for complex infrastructure projects. With increasing demands for sustainable infrastructure and innovative structures, selecting a structural engineer or a team of structural engineers with the right expertise is crucial.

Why Specialized Structural Engineering is Needed for Manufacturing Plant Construction Projects

Manufacturing plants aren’t your average buildings. They’re dynamic environments where heavy equipment, constant vibration and strict safety standards collide. That’s where civil engineers and structural engineering companies come in. They work together to ensure foundations can bear massive loads while using advanced software to model and refine every detail. A flaw in structural design doesn’t just delay construction—it risks operational downtime and millions in losses.

According to a 2022 McKinsey report, poorly planned infrastructure projects can add up to 30% to construction costs. For manufacturing plants, structural engineering isn’t optional—it’s the foundation of success.

Structural engineers in these facilities need to design safe building systems that contribute to project efficiency and minimize construction costs.

- Structural engineering plays a key role in infrastructure development by analyzing loads and designing structures that can withstand environmental forces.

- Civil engineers and structural engineers must work together to integrate advanced software and digital design services that meet safety standards while reducing environmental impact.

- In manufacturing plant construction, every structural engineer must address complex projects by providing innovative solutions that support sustainable development and optimize project management.

That means structural engineering companies with a history of delivering comprehensive services and innovative approaches stand out. Their ability to merge global design practices with local feasibility studies is key to improving efficiency and safety. Learn how integrated vendor solutions can optimize your manufacturing plant project.

How to Evaluate Structural Engineering Companies

Choosing the right firm for manufacturing plant projects requires a keen eye for specific strengths. Here’s what to look for:

Experience and Expertise:

When evaluating structural engineering companies, you want to look for those with experience and expertise in industrial settings. They should understand the needs of manufacturing plants—think load-bearing capacities for machinery or seismic resilience in earthquake-prone areas. Firms with a history of infrastructure projects have knowledge that generic companies can’t match.

You want to see companies with decades of engineering experience in industrial projects and large-scale projects. Civil engineering teams should have worked on multiple projects in high-profile locations say San Francisco or under constrained environments.

Proven Track Record with Projects

A proven track record with projects is also key. Structural engineering companies with a portfolio of manufacturing plant projects show reliability. Look for firms that have worked on similar scales, showcasing innovative approaches to complex infrastructure projects. Case studies or client testimonials can reveal how they handle real-world challenges, from tight timelines to budget constraints. For instance, you can find detailed portfolios of vendor’s completed project and innovative approaches in action here.

Advanced Software and Digital Integration:

Advanced software and digital integration are also essential. For manufacturing plant projects, these digital tools are the backbone of modern structural engineering. They enhance project management by providing accurate shop drawings and collaboration among civil engineers and structural engineers.

Key tools:

Revit BIM Services:

Integrates structural design with BIM services to create a coordinated digital model. This simplifies project management by providing accurate shop drawings and collaboration among civil engineers and structural engineers.

Such integration supports innovative solutions that meet safety standards and reduce environmental impact. Find out how BIM services can streamline your design process, see here.

Tekla Structures:

Known for its steel detailing capabilities. It have features for structural engineers to model, detail and coordinate every building component accurately – improving efficiency and safety in complex projects.

AutoCAD and FEA Tools:

Used for drafting services and feasibility studies. These tools produce precise construction services deliverables that reduce reworks. Learn more about CAD drafting precision here.

Digital integration is a major driver of project efficiency and is a key factor when evaluating structural engineering companies for your manufacturing plant.

Detailing Services:

Top structural engineering companies offer steel detailing, precast detailing and rebar detailing. They ensure every building element is made accurately, so it reduces construction costs and speed up on-site construction.

Their services must cover both the structural design and the detailed drafting needed for safe operations.

Steel Detailing:

Providing detailed shop drawings that specify every aspect of steel detailing ensures engineers can fabricate and erect components with precision. This also minimizes waste and errors during construction.

How exert steel detailing services can optimize your manufacturing plant project, see here.

Precast and Rebar Detailing:

When precast detailing and rebar detailing are done correctly, construction becomes less labor intensive. This reduces construction costs and shortens the project timeline. Discover comprehensive Precast Detailing Solutions by expert vendors.

These services are important for manufacturing plant projects where off-site fabrication is a key strategy.

Drafting and CAD Services:

Using advanced software for drafting services ensures every design service is accurate and coordinated. This reduces project delays and ease the challenges during construction. Explore high-precision drafting services.

Project Management and Coordination:

success doesn’t come from engineering in isolation. Project management is where the real magic happens. The best firms know how to bring together civil engineers, architects and project management teams in seamless collaboration. That synergy is what ensures every aspect of a manufacturing plant—foundation to roof—aligns perfectly. Companies that prioritize communication and planning deliver comprehensive services that drive real results. Those that combine engineering with robust project management practices can handle construction challenges and offer innovative solutions.

Sustainability and Environmental Impact:

With increasing focus on sustainable development, while choosing a structural engineering company, look for evidence of sustainable infrastructure in their past projects – low environmental impact and high project efficiency.

Real success in project outcomes comes from structures built to the highest quality, with minimal risk and maximum efficiency.

Top Structural Engineering Firms in India

When it comes to selecting top structural engineering firms for manufacturing plant construction, the choice of vendor is crucial. A robust manufacturing plant demands resilient design and integrated, innovative solutions—from steel detailing and precast detailing to BIM integration and advanced CAD services. Here are a few of the top structural engineering firms in India that have made a mark in the global design and engineering landscape.

J&F

A prime example of a vendor with a presence across multiple regions. Their diverse portfolio ranges from airports and commercial buildings to manufacturing plants and data centers. They’ve delivered projects like the Michelin India Tire Factory and high-rise renovations in Berlin. Their ability to combine BoQ/QS services with detailed BIM modeling makes them a key partner for large scale manufacturing plant projects.

👉 J&F

Mold-Tek Technologies Limited

Mold-Tek Technologies Limited has a strong track record of serving over 1,100 chemical plants and various industrial facilities. They specialize in structural steel detailing and precast detailing. Their precision is critical for the heavy-duty requirements of manufacturing plants. Projects like MOLSON Coors and SCI Mission show their capability to handle industrial and commercial sectors.

👉 Mold-Tek Technologies Limited

GBC Engineers

Known for PEB design and BIM modeling. Their projects like the Tesla Gigafactory in Berlin-Brandenburg and Siemens Campus Erlangen demonstrate their ability to integrate modern design services with project management for infrastructure projects. Their work in manufacturing plant construction is a testament to their innovation and reliability.

Aarbee Structures Private Limited

Aarbee Structures Private Limited provides specialized services in structural steel detailing and precast detailing. With projects from Las Vegas Raiders Stadium to Port Everglades Terminal 25, they excel in converting complex engineering requirements into shop drawings and detailed models. That ensures construction management and cost control.

👉 Aarbee Structures Private Limited

Oriole Design Tech Solutions LLP

Oriole Design Tech Solutions LLP offers 3D modeling, coordination and shop drawing services. Their digital planning and clash reporting capabilities help streamline construction services for manufacturing plants, reducing rework and improving project efficiency.

👉 Oriole Design Tech Solutions LLP

Arup: Pioneering Global Design

Founded in 1946 by Ove Arup, brings a visionary approach to structural engineering. Known for Sydney Opera House, this London based firm has a San Francisco office and has worked on complex projects. For manufacturing plants, Arup’s civil engineers and structural engineers work together to deliver sustainable infrastructure. Their project management expertise was seen in Tesla’s Gigafactory in Nevada where they optimized structural design for rapid assembly and operational flexibility.

Jacobs: Comprehensive Services for Infrastructure

Jacobs, a Dallas based giant offers a wide range of professional services from planning to construction management. With over 55,000 employees worldwide, they have worked on large scale projects like ExxonMobil Baytown Refinery expansion where structural engineering ensured safety and scalability. Their civil engineering teams work with structural engineers to address manufacturing plant challenges like heavy equipment foundations making them a versatile choice for infrastructure projects.

WSP: Engineering with a Sustainable Edge

WSP, with a history dating back to 1885, combines heritage with forward thinking engineering. Operating globally including in San Francisco, they prioritize sustainable development in structural engineering. Their work on General Motors Factory ZERO in Detroit shows their ability to renovate manufacturing plants for modern needs, with energy efficient building systems. WSP’s structural engineers use advanced software to minimize environmental impact, in line with industry trends towards sustainable infrastructure.

Thornton Tomasetti: Precision in Complex Projects

With over 70 years of engineering experience, Thornton Tomasetti is known for innovative solutions in structural engineering. Headquartered in New York, this firm has a global presence with offices in San Francisco. They’ve worked on iconic projects like Apple Park in Cupertino where structural engineers designed a ring shaped marvel with seismic base isolation – a testament to their ability to handle complex structures. Their use of advanced software for modeling and analysis makes them a go-to for manufacturing plant projects that require precision under pressure.

Conclusion: Build with Confidence

Structural engineering companies for manufacturing plant projects aren’t just about who you know – they’re about partners that can turn challenges into opportunities. Companies like J&F India, Mold-Tek Technologies Limited, GBC Engineers and Aarbee Structures—each with their own strengths—can help you build infrastructure that lasts. That real-world impact is what drives operations-and what shapes the built environment for decades to come. Your structural engineer should be the foundation on which you build that success.

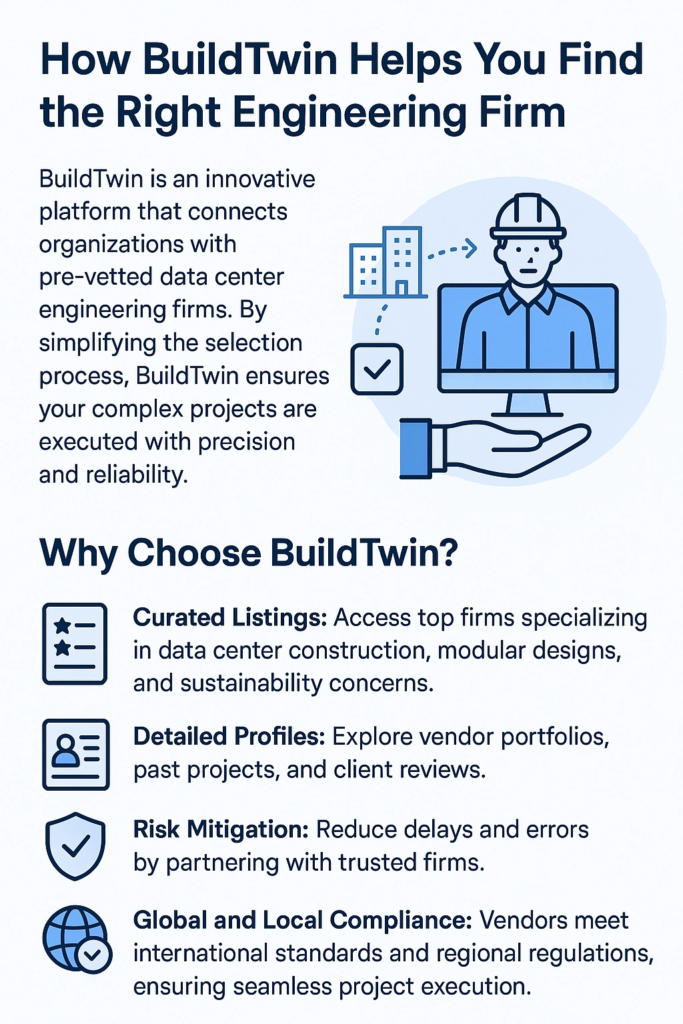

Ready to take your project to the next level? Start exploring BuildTwin’s vendor network today.